JuniorEnthousiast

Well-known member

I have long since wanted a Danelectro guitar and especially a DC. I just think they sound so cool. The Made In China reissues don't exactly tickle me though and being a lefty there aren't many old stock DCs to be had.

Oigun, my luthier buddy, told me to get a cheap righty from the interwebz that we'd rip the top off to make room for a lefty-fied top.

I'm an impatient SOB and in the last year every Dano I came across on the eBay either went for more than I was willing to spend or was a MiC.

Then I found this neck;

It's got the Coke bottle headstock that I like way more than the goofy new style heads.

Some nice D-stamped tuners!

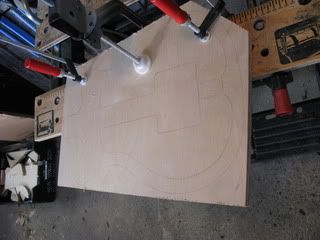

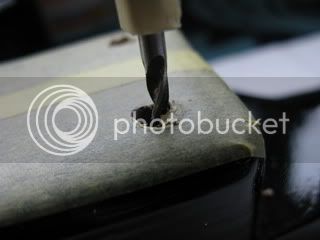

I figured a Dano wouldn't be real hard to make, and since I won the auction for the neck, seller included some other nice Dano stuff too, why not give building one from (kinda half-way) scratch a go?

Oigun, my luthier buddy, told me to get a cheap righty from the interwebz that we'd rip the top off to make room for a lefty-fied top.

I'm an impatient SOB and in the last year every Dano I came across on the eBay either went for more than I was willing to spend or was a MiC.

Then I found this neck;

It's got the Coke bottle headstock that I like way more than the goofy new style heads.

Some nice D-stamped tuners!

I figured a Dano wouldn't be real hard to make, and since I won the auction for the neck, seller included some other nice Dano stuff too, why not give building one from (kinda half-way) scratch a go?